Are you looking for a complete plastic hijama cupping production line, along with high – quality machines and molds? Look no further! This guide will tell you everything you need to start your hijama cupping manufacturing business.

Essential Equipment for Hijama Cupping Production

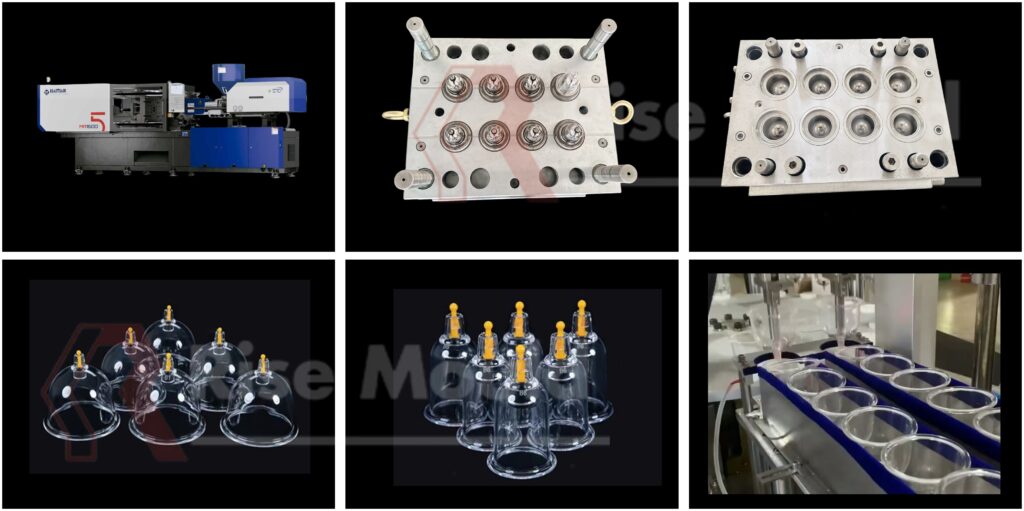

To make plastic hijama cupping, you need two main pieces of equipment:

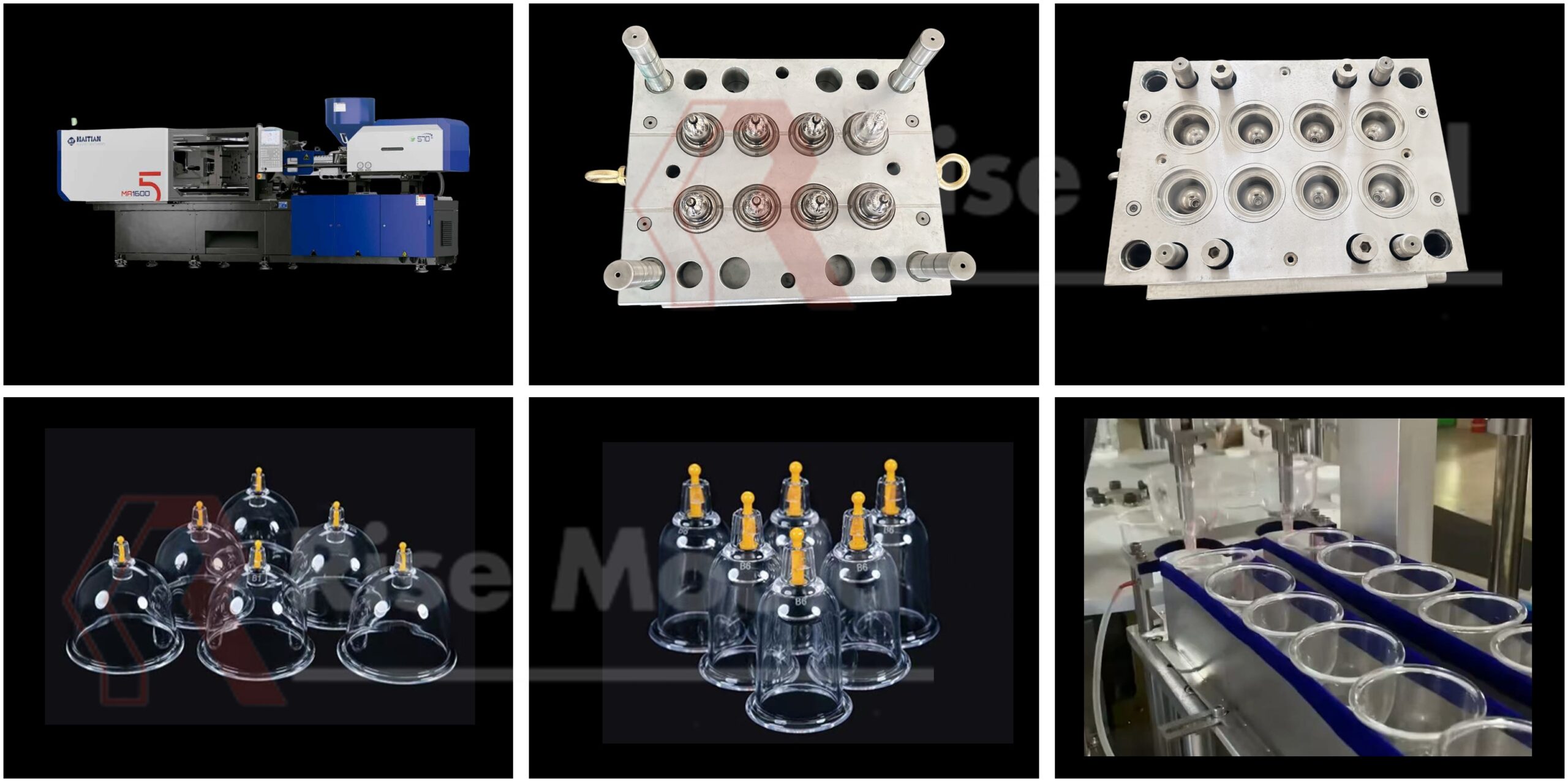

- Plastic Injection Molding Machine with Plastic Injection Molds: This is needed to make the cupping bodies. Our well – made plastic cupping molds help make products of good and consistent quality.

- Automatic Assembly Machine: It puts all the parts together quickly, making the production process go smoothly. You need both of these machines to set up a good production line.

Mold Requirements

Usually, a set of plastic hijama cupping comes in 6 – 8 different sizes. So, you need 6 – 8 sets of molds. At RISEMOULD, we know how important good plastic hijama cupping molds are for production. As a top mold factory, we’re the perfect partner for you.

Why Choose RISEMOULD?

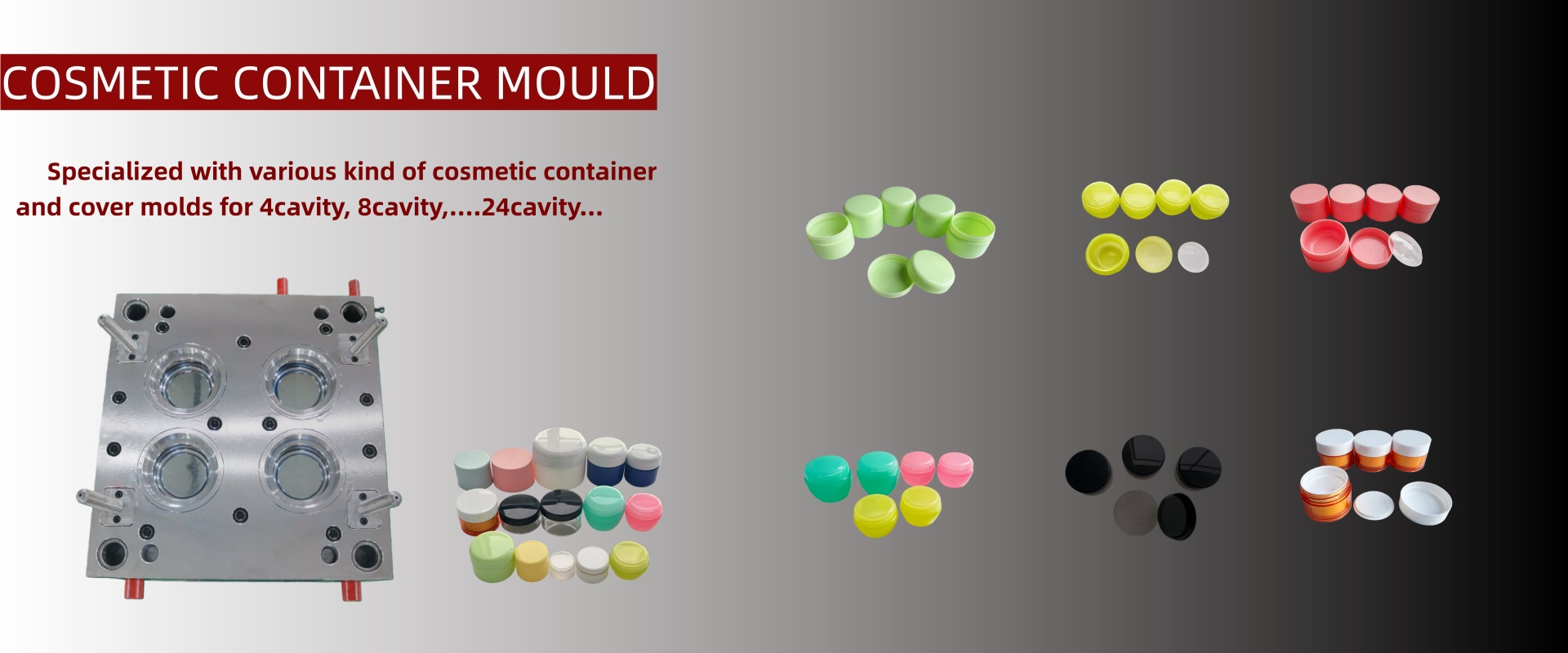

We make high quality plastic injection molds for cupping bodies and handles with advantages for delivery time, service and project attention. We also offer assembly machines for plastic cupping production. With us, you get a full plastic cupping production line solution.

Want to start or improve your plastic hijama cupping production? Contact RISEMOULD now!

contact: email: export@risemould.com

whatsapp/wechat: 0086 15967609692