Concentration Makes Profession

Concentrated on multi-cavity packing mould solution for decades

5000+

Over 5000+ package mold expierence

300+

Annually make over 500+molds

50+

Export to over 50+ coutries

Our Services

Mold Design

Expert mould design services tailored to your specific requirements, ensuring precision and top quality. A design team with over 15 years of experience, focusing on lid mold and PET mold design.

Mold Manufacturing Solutions

Adopt high precesion mould tooling equipmentEfficient and reliable manufacturing solutions that guarantee fast turnaround times without compromising quality.

One Stop Solution for packaging

Provide one stop service for packaging solution such as cap slitting machine, cap assembly machine, PET blowing machine… to help the customer start new production line easily and quickly.

About US

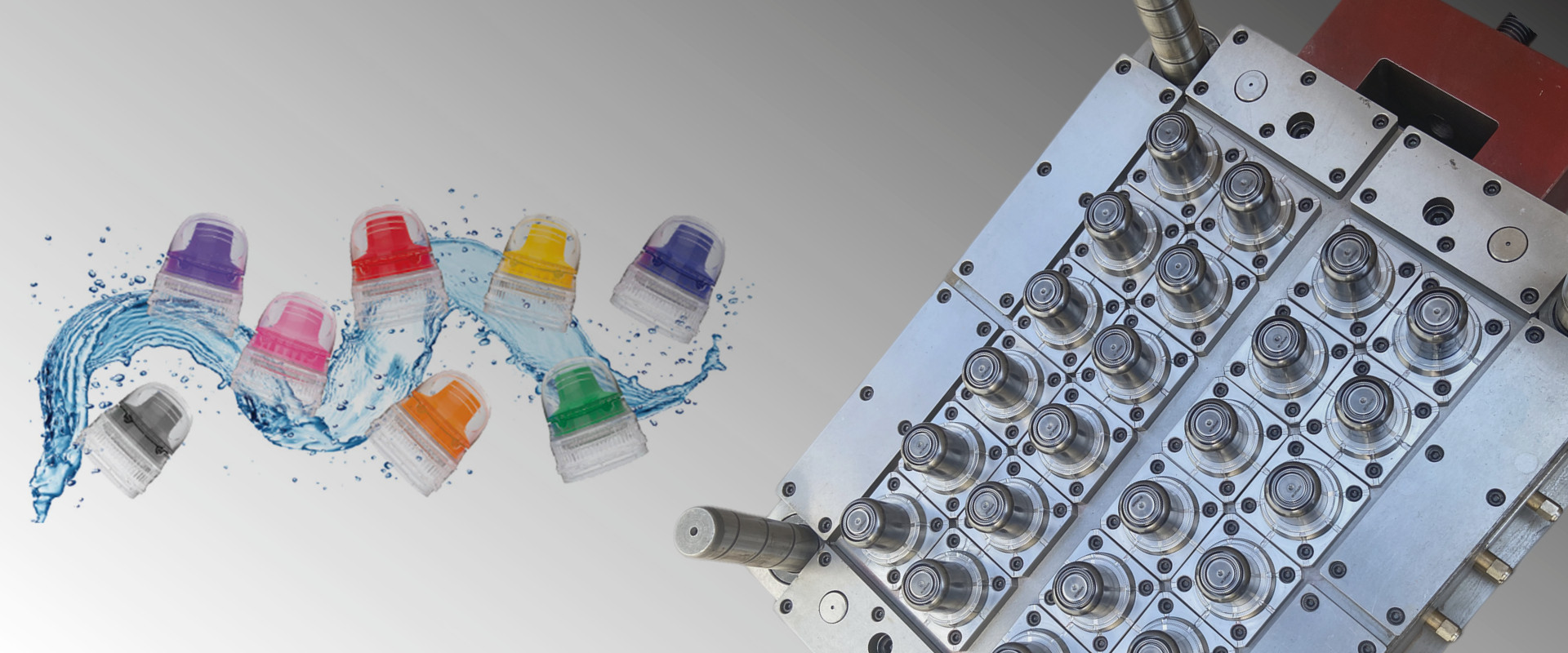

RISEMOULD is a professional Chinese mould maker specializing in design and manufacturing of packaging molds, such as PET preform mould with multi-cavity solution, cap mold, container molds, blowing mold… with over 15 years of experience in packaging molds. We have made 80% types of bottle cap molds in the market. We are passionate about delivering high-quality, high-precision, and high-efficiency packaging molds.

With years of expertise and a dedicated team, we ensure precision, durability, and efficiency in every mould we produce. Our commitment to excellence drives us to constantly innovate and exceed mold standards, providing our clients with the best solutions for their packaging needs.

Professional design

RISEMOULD have a team of designers with over 15 years of PET preform mould and cap mold design experience, consisting of 3D cap product design, 3D preform mold design, 2D and MOLDFLOW simulation, with software UG, SOLIDWORKS, AutoCAD…We will study the feasibility of Design for manufacturability from different aspects, such as thickness, strength, possible molding defects… to offer professional suggestion to our customer for optimal product design and prevent defects in advance.

We will do MOLDFLOW analysis to find suitable injection gate location, type and qty of HRS tips to get a best material filling effect and improve defects like welding line, air trapped, and deformation.

Global Partner

To offer better service and quality to our customer, RISEMOULD have established good relationship with many global partners for spare parts, steel and hot runner. For example:

- Hot runner: Yudo, Moldmaster, husky hot runner

- mould base: LKM, DKM

- Steel: Germany thyssenkrupp, Germany Gröditz, Sweden ASSAB

- With imported steel like,1.1730,1.2311,1.2738,,1.2344,S136,1.2083,1.2085,NAK80…

- And mould spare parts like HASCO, DME, Staubil, and Schneider limit switch, Parker hydraulic system…

High Precision Tooling

RISEMOULD use advanced equipment such as wire cutting, 5 axis high speed CNC center, high speed lathe machine…for tooling to make sure the preform mold and cap mold quality. For all the parts, RISEMOULD will have 2D drawing with clear tolerance requirement. According to part requirement, we will arrange suitable tooling equipment. For the main parts, RISEMOULD will inspect the dimension and only parts that meet the tolerance requirements can flow to the next step.

Simulation test

When the mould is ready, RISEMOULD will test the mould and send samples for approval. For each mould before delivery, we take 2-4hour continuous running to make sure the cap mould works perfects without any problems. Its believed a small problem here in RISEMOULD will be a big problem for customer. So we will do our best to discover and solve the problems in RISEMOULD. Our target is help our our customer start cap mold running quickly and smoothly in their factory.