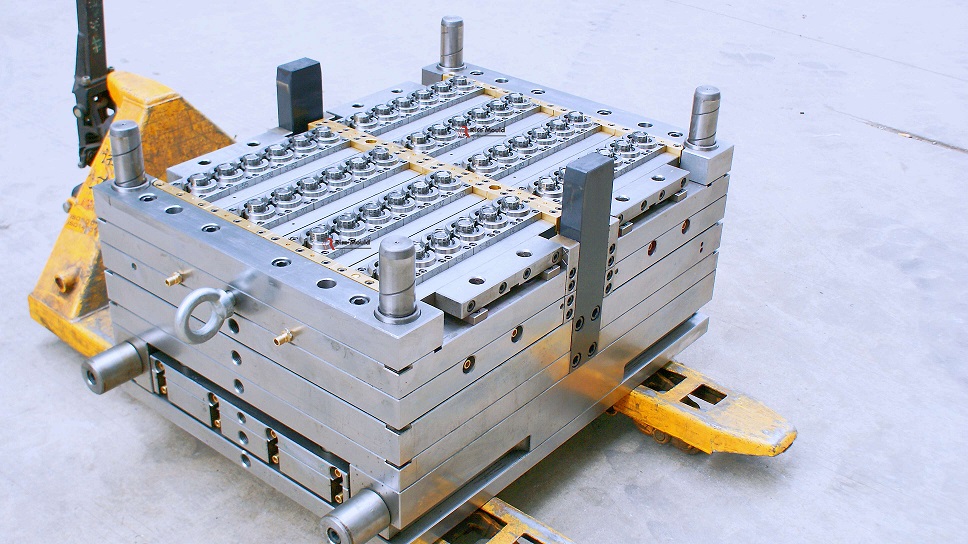

RISEMOULD have good expierence for making cap molds from 16cavity, 48cavity, 72cavity. below are some mould specs for 48cavity water cap molds.

| Cap Specs | Cavity No | Mould Specs | Recommend Machine Size |

| 1881 water cap | 48 | 790x630x630mm | 350T |

| 1881 water cap/3025 water cap | 48 | 790x630x630mm | 350T |

| 1810 water cap | 72 | 1050x630x750 | 450T |

| 45mm cap | 24 | 800x640x615 | 350T |

| Cap Mold Specs | Cavity No |

| Mold specs | water cap mold |

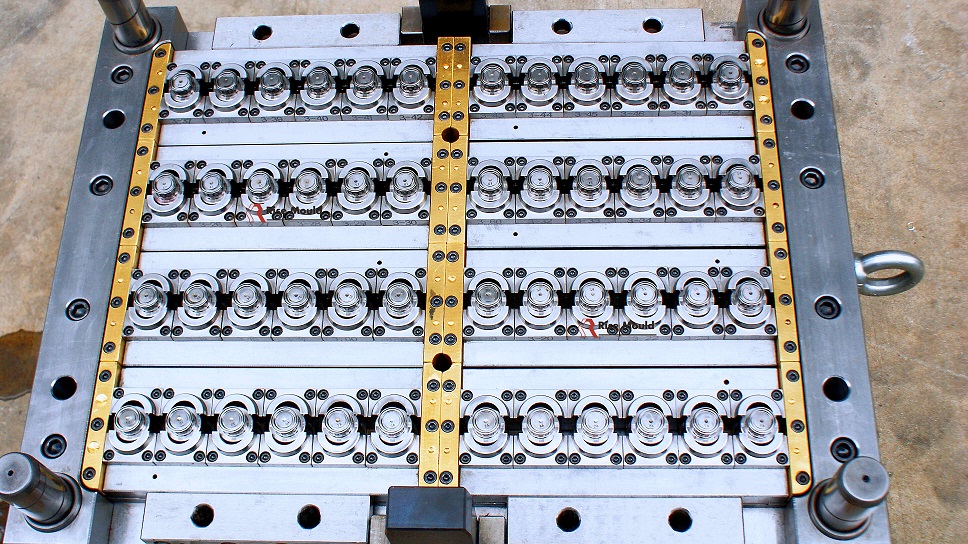

| Mould Cavity no | 16,24,32,48,72 |

| Mold Gate | hot runner point gate |

| Core&Cavity Mold steel | S136 steel, 2083 steel… |

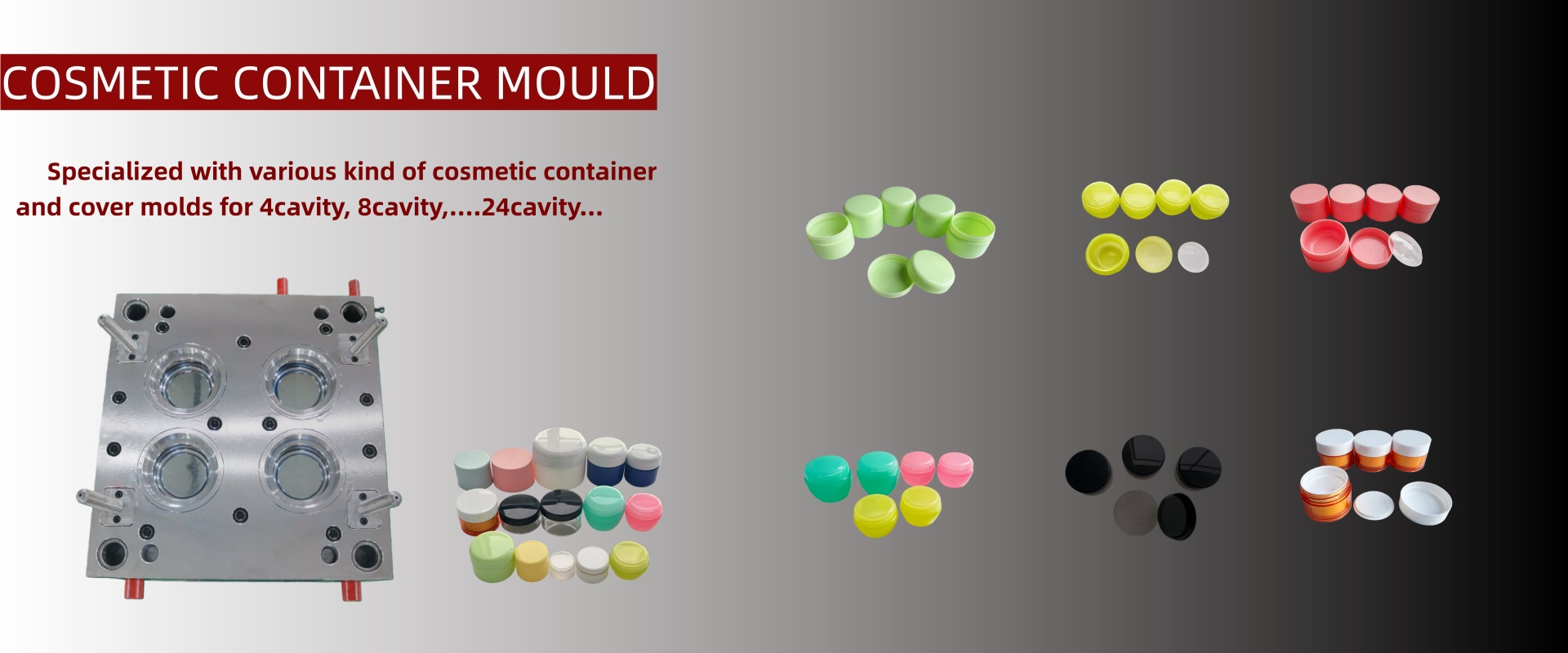

| Auxiliary cap machine | We also offer cap slitting and folding machine as one stop solution |

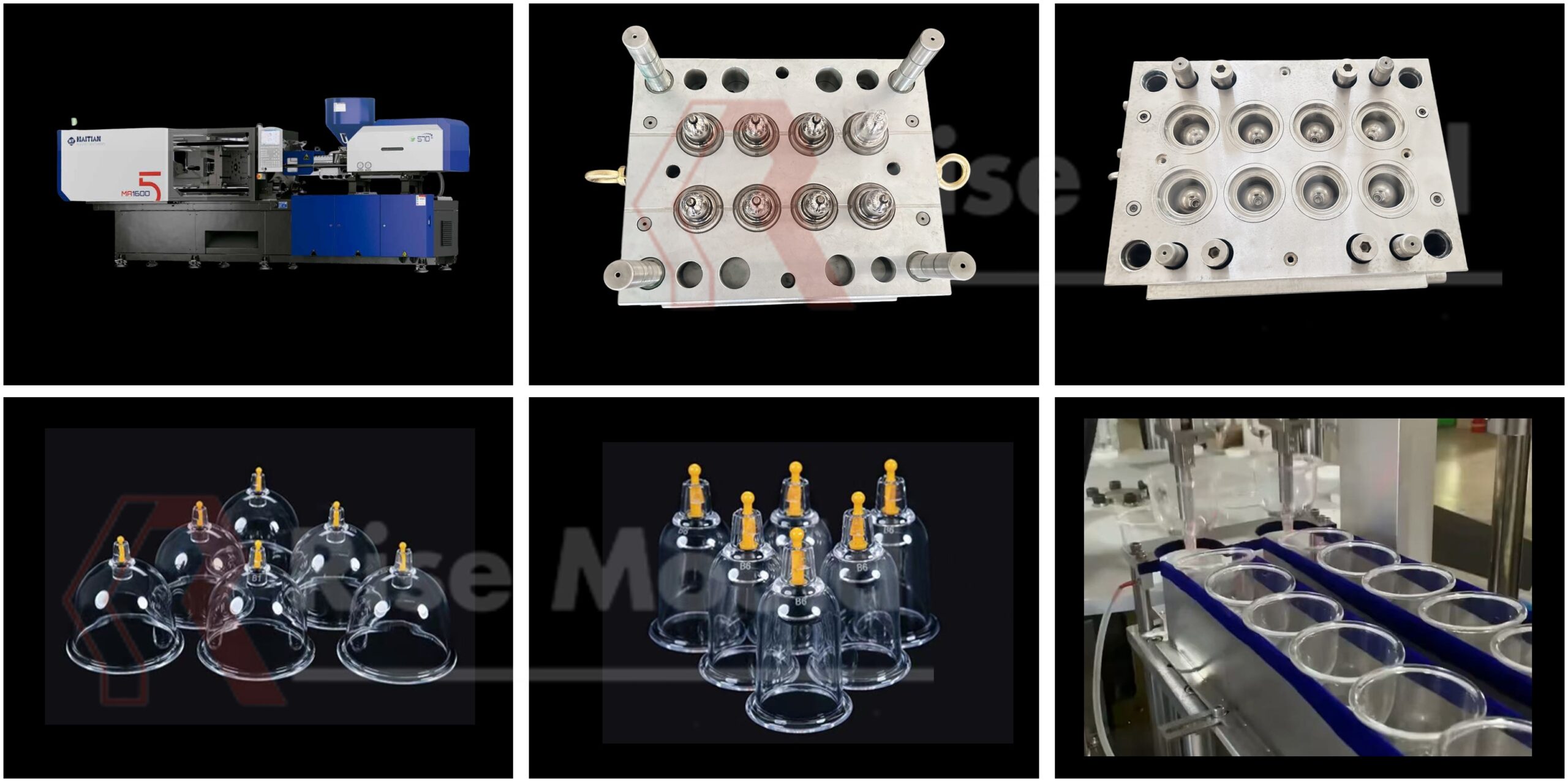

RISEMOULD control each step strictly from design to manufacturing to make sure the final quality of molds.

1-design stage. we will do product and mold design for each cap product. for the design stage, we will inpsect each details carefully to make sure the cap design is optimal. and during mold design stage, we will check gate syste,, runner system, ejection system one by one to make the mold will correctly.

2-manfucturing stage. we use high precision equipement such as high speed lathe machine, high speed CNC milling machine.. to make sure the high precsion of each mold.

3-testing stage. we will do fully test of each mold before shipment. we will make samples after mold is complete and send samples to customer to check before delivery.

4-After sales support. we will guide you to run the mold after shipment if you meet any doubts in using the cap mold.

RISEMOULD deliver high quality water cap mold for different cavities. welcome to contact us for quotation!

Email:export@risemould.com

Whatsapp/wechat 0086-15967609692